- #DIPTRACE PCB LAYOUT TUTORIAL HOW TO#

- #DIPTRACE PCB LAYOUT TUTORIAL UPGRADE#

- #DIPTRACE PCB LAYOUT TUTORIAL VERIFICATION#

- #DIPTRACE PCB LAYOUT TUTORIAL SOFTWARE#

- #DIPTRACE PCB LAYOUT TUTORIAL PROFESSIONAL#

I assume that different CAD tools have different ways of implementing this form of verification.

#DIPTRACE PCB LAYOUT TUTORIAL VERIFICATION#

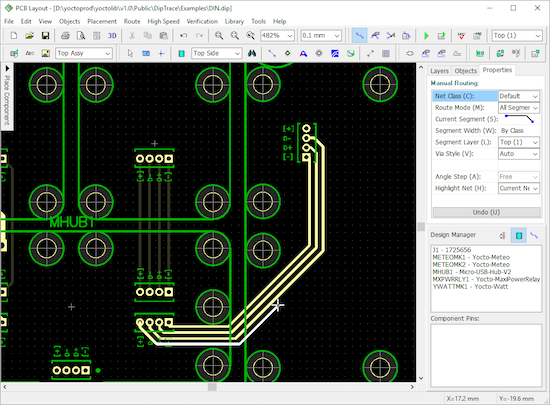

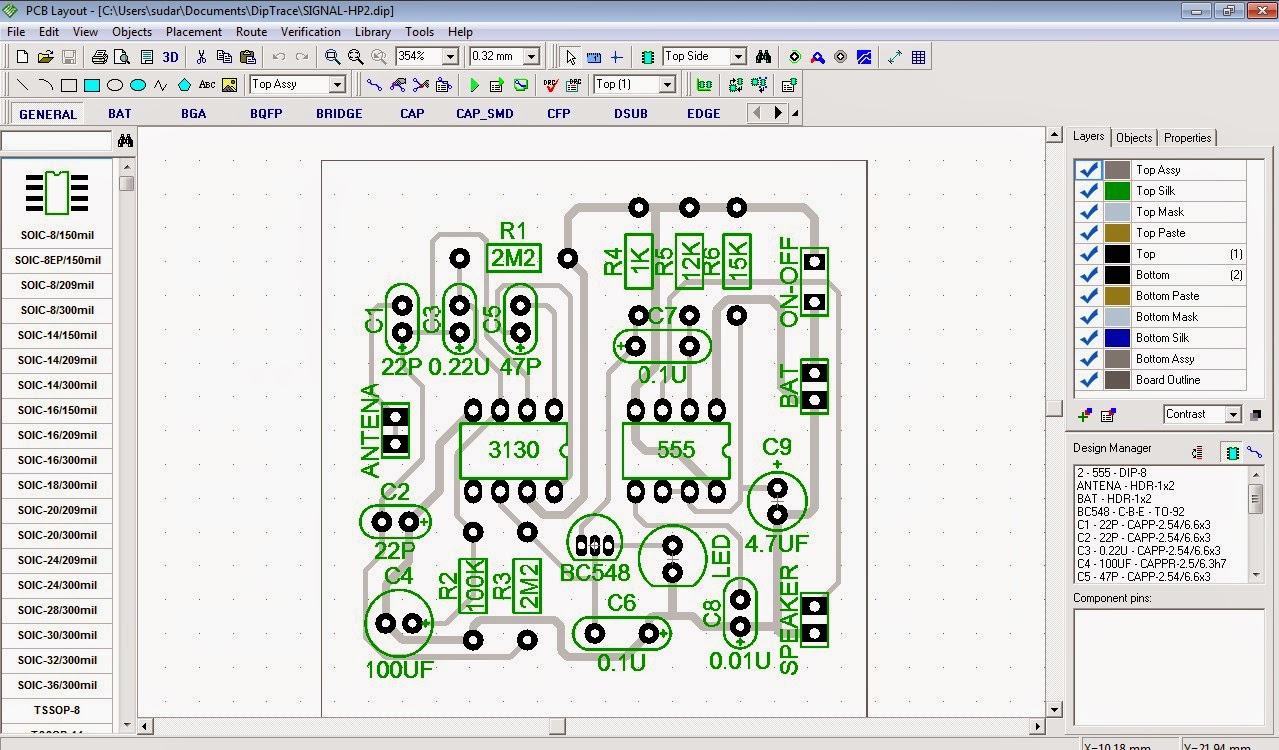

I’m familiar with three types of verification (though maybe there are more): The general idea here is that the CAD tool attempts to find layout mistakes before they negatively affect the board’s functionality or interfere with the manufacturing process. The final step before the beginning of the manufacturing stage is referred to as verification. Verification: Identifying Issues in PCB Layouts A via is a small through-hole that carries an electrical connection to a different PCB layer (or to multiple layers-e.g., a thermal via might connect to the internal ground plane and a ground-connected copper pour on the bottom of the board). The designer arranges components and then uses the ratlines as a guide for creating traces, copper pours, and vias.

#DIPTRACE PCB LAYOUT TUTORIAL SOFTWARE#

The following image provides an example of a schematic component and the corresponding PCB footprint (the blue lines indicate the footprint pad to which each component pin is connected).Ī completed schematic is converted by CAD software into a PCB layout consisting of component footprints and ratlines this rather unpleasant word refers to electrical connections that have not yet been converted into physical connections. These show up on the PCB as purely visual elements they’re not conductive and do not affect the functionality of the circuit. A footprint can also have lines, shapes, and text that are collectively referred to as the silkscreen. The components include a footprint (AKA land pattern), i.e., a collection of through-holes and/or surface-mount pads that match the terminal geometry of the physical part. The wires will become traces or copper pours.

#DIPTRACE PCB LAYOUT TUTORIAL HOW TO#

How to Generate Manufacturing Files for Custom Printed Circuit BoardsĪ schematic consists primarily of components and wires connected in such a way as to produce the desired electrical behavior.Guide to Ordering and Assembling Printed Circuit Boards I sincerely appreciate your contributions. Nonetheless, I am only one person and I most certainly cannot know everything, so please do not hesitate to expand upon my work via the comments section at the end of the article. I’ve been doing independent and low-quantity PCB design for a long time, and I’ve gradually acquired enough relevant information to put together a reasonably comprehensive article on the subject.

#DIPTRACE PCB LAYOUT TUTORIAL PROFESSIONAL#

Professional PCB fabrication is so affordable and convenient these days, and in general the results are far superior. By “manufacturing” I mean “paying a company to manufacture”-I will not discuss DIY fabrication of PCBs, and I can't honestly recommend that approach.

This article is intended for anyone who is interested in (or might someday be interested in) manufacturing and assembling small quantities of high-quality PCBs. Even if you’re somewhat familiar with ordering and assembling PCBs, you might not be aware of some options that could help you to achieve adequate results at lower cost. We shouldn’t forget, though, that schematics and layouts aren’t very useful if you don’t know how to turn your finished design files into an assembled circuit board.

There is no doubt that schematic creation and PCB layout are fundamental aspects of electrical engineering, and it makes sense that resources such as technical articles, app notes, and textbooks tend to focus on these portions of the design process.

#DIPTRACE PCB LAYOUT TUTORIAL UPGRADE#

It is included in the DipTrace installation package.Ī 30-day full-featured trial, various DipTrace Editions and upgrade without overcharge will satisfy even the most cost-concious managers.This article gives a high-level view of the basics of preparing a schematic for custom PCB fabrication. The tutorial contains detailed instructions for all stages of the board design. Basic features are enough for simple projects and advanced capabilities should be used for complex circuit boards.Īll DipTrace modules share similar interface conceptions and design basics. Advanced verifications and Real-time DRCĪfter a couple of hours you become productive with simple boards and then improve your skills step-by-step.Multi-sheet and hierarchical schematics.DipTrace is a quality Schematic Capture and PCB Design software that offers everything to create simple or complex multi-layer boards from schematic to manufacturing files.ĭipTrace is a first of its kind intuitive CAD software, featuring:

0 kommentar(er)

0 kommentar(er)